SERVICES

Machining

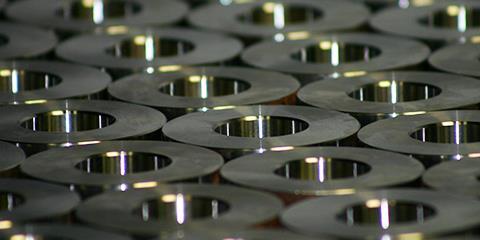

We are an expert partner of machining with the experience of tens of years. Our modern machinery is capable for very challenging machining and our professional staff is ensuring high quality and flexible delivery times according to our customer needs. Continuous development of our production equipment and the newest CAD/CAM software are enabling the use of modern machining methods. A good example of this is a 5-axis machining method, we can use in many different kind of machine tools. All our machine tools are also regularly mantained and hence reliable.

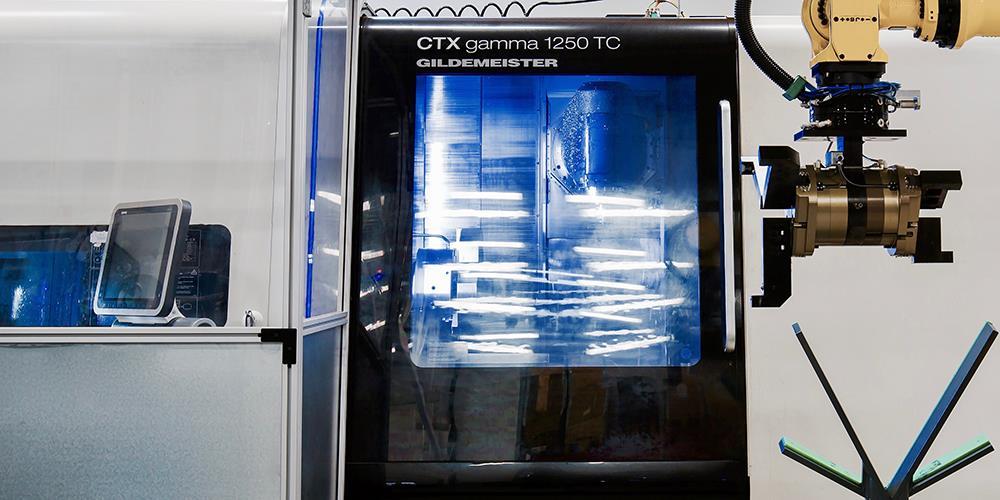

CNC-Machining / TURNING

- Shaft type components

- Max. diameter 900mm

- Max. lenght 3000mm

- Flange type components

- Max. diameter (1250mm)

CNC-Machining / MILLING

- Max. Height 1200mm and Lenght 3000mm

Semi-finished components

Alongside with machining, we also manage different kind of assembly works, both on a small and on a big scale, depending on the customer needs.

For example:

- Seal Installations

- Dustcover Installations

- Installations / agglutinations of insulator element

- Tag labels and other markings

- Packing products for sale packages

Delivery of different mounting kits according to the customer configuration

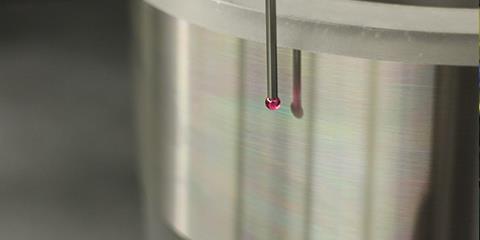

Measuring and quality

In our factory we have wide range of regulary serviced modern measuring devices. From hand held devices to big size coordinate measuring machine. With it we can prove our capacity in challenging pieces. Measuring is one of the most important things when comes to quality and thats why we have invested in it.

With 3D measuring we can verify the piece and ensure that everything is all right. Our 3D measurement service has been one of the functions that has increased our customer satisfaction.

Working area dimensions 1200mm x 1000mm

The base of our operation are ISO9001 and ISO14001, our quality and environmental system. In the last years we have invested in following the quality of the return together with supervision and we can answer customers needs in this are too.

We use for quality control the following measuring tools among other things:

- PPAP

- SPC

- PSW

- 5D

- 8D

- FMEA

- SIPOC

Materials and Collaboration Network

Because of our comprehensive collaboration network, if nessecary we can deliver orders to customers, completely finished.

For example including:

- Raw material sourcing

- Necessary annealing, hardening or other heat treatment

- Welding

- Surface Treatments

- Sandblasting

- Ball blowing

- Painting

- Nitration

- Galvanizing

- Passivation

- Etc.

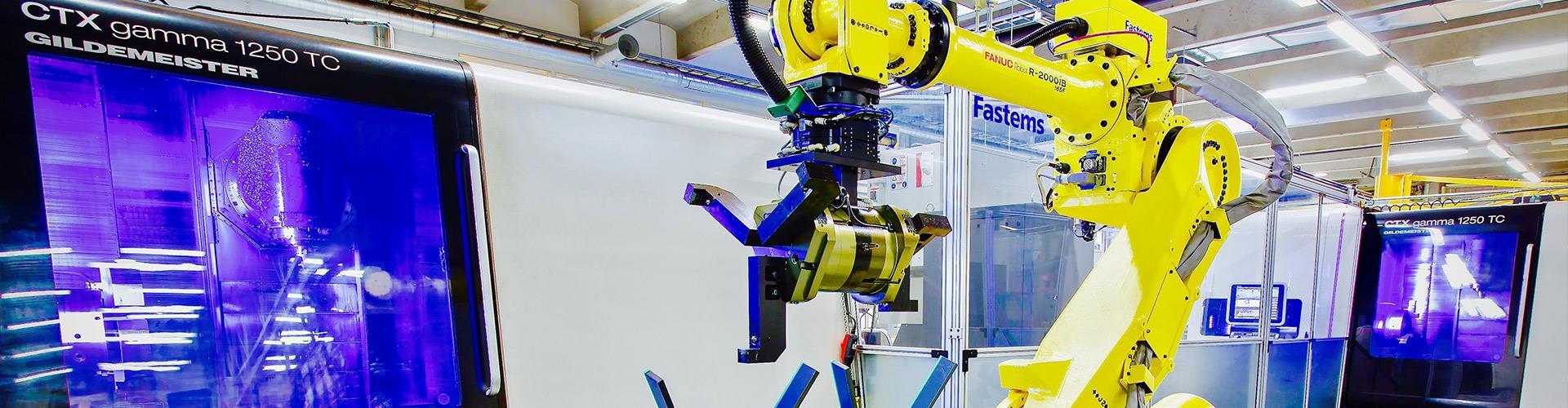

Automation

The investments we have made in our automated production contribute to our production efficiency and flexibility as an essential part. The flexible and versatile use of robotics in different stages of our production have improved our quality and price competitiveness noticeably. Batch sizes vary from one to thousands of pieces and especially in large batches, the benefits of production automation are noticeable to the customer.